I went on a study tour to Japan this year to look for insights. We had the honor of visiting companies like Fujitsu, Toyota and a two young, agile software shops. If you have ever visited a assembly floor in Toyota you realize that invention has been happening for years and are very much ongoing. They have never stopped. Why?

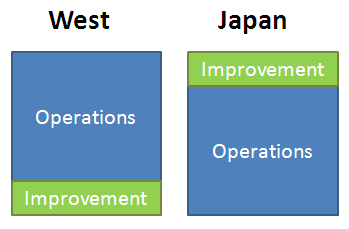

One of the answers can be found in the attitude. While we (in west) see improvements as something extraordinary, improvements are in Japan the essence of operations. It is so rooted in the company culture that it has a separate name, Kaizen.

While we succeed in copying improvement activities -retrospectives, quality circles, SPC charts etc, we have much more to learn about adopting the mindset that makes people question and carry through improvements.

As one CEO remarked:

"The one question I have to answer to at the end of the year is – what have you improved?"

In scrum you usually have demo+retrospective one day and next sprint planning the day after/next week.

Have you tried to have the demo one day. And retrospective + sprintplanning the next day?

There are many ways of doing improvements. My point is, the attitude we have towards doing improvements, is one of the first blockers. Here we have much to learn.