Continuous improvement is a central part of both agile and lean; it’s the way to increase the productivity and ensure that the organization delivers an ever increasing level of value to the customers and the organization. Lean is derived from Toyota and the Toyota Way, which has inspired a lot of companies in the western world in their quest to increase their productivity as well. But we often focuse on the techniques and practices and do not see the more fundamental parts of the Toyota system that enable their very high level of improvement each year.

I worked at a company that tried to implement the Toyota Way and reach the same level of continuous improvment with what I believe to be the wrong focus. My company estblished a goal to reach seven improvements per employee in average per year. A goal that was inspired from a report that stated that Toyota implemented 1,000,000 improvements per year, which of course, is very high. This is one of many aspects that show why Toyota has managed to grow they way they have done during the last 50 years.

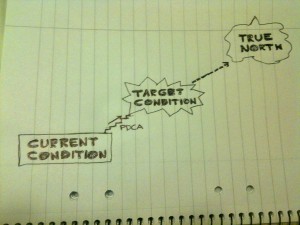

At Toyota they implement improvements as a way to learn things about their processes. Toyota has a ”True North” that is an ever-existing direction that they strive for during their improvements, which is reaching true continuous flow with zero defects. Toyota does not spend time arguing if this is a reachable goal or not, they have it as a direction that they try to reach day by day. But to have a more concrete target, they also establish the next target condition for a process. This is something that is a challenge to reach, but still is achievable. With a target condition they start a series of experiments according to the PDCA cycle, where they for each step increases their knowledge and understanding of current problems that are stopping them from working according to the goal. They try to take really small steps so that they increase their learning. If you take too large step at a time you will have a slow learning velocity, but also the environment and conditions will likely have changed so that you have a hard time understanding what have happened during the experimentation. Target conditions is different compared to using targets. A target could be to decrease the leadtime to 5 days, or to decrease the level of defects to 100. The problem with using a target to drive your continuous improvement is that the target doesn’t tell you anything about what you are trying to achieve, it do not give you any details and it can not guide you towards your goal. Toyota uses targets, but it is the target condition that points you and help you evaluate the improvements to see if they are going in the right direction and really improve your system or not.

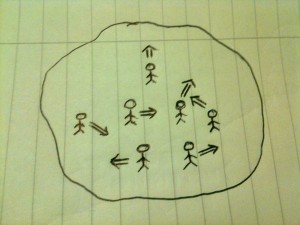

The company I was working at tried to increase the level of improvements. The goal was a very good one taken with good intentions, but the problem was that they focused on the number of improvements instead of what we were improving and producing during our daily work. We got targets that we needed to reach during the year. At first this target was three improvements per employee on average, and the plan was that we should reach seven improvements per employee the next year. Seven improvements per employee are considering being at the top level of companies striving for lean, so my company reached for the top position.

This was a focus on the outcome, not on why we do the improvements in the first place. We didn’t have a target condition and therefore no direction so the improvements couldn’t build on each other. I’m certain that we could have reached the next target of seven improvements per employee, but I do not think that we would have increased our knowledge of how we developed products, or improved the productivity due to this, we might have even decreased it in reality. Every employee and manager was monitored during the year to see how many improvements they had implemented. This was something that was discussed during the all-hands meetings as well as during the one-and-ones. But, interestingly, we never discussed what we had gained from each one of the improvements!

This was a focus on the outcome, not on why we do the improvements in the first place. We didn’t have a target condition and therefore no direction so the improvements couldn’t build on each other. I’m certain that we could have reached the next target of seven improvements per employee, but I do not think that we would have increased our knowledge of how we developed products, or improved the productivity due to this, we might have even decreased it in reality. Every employee and manager was monitored during the year to see how many improvements they had implemented. This was something that was discussed during the all-hands meetings as well as during the one-and-ones. But, interestingly, we never discussed what we had gained from each one of the improvements!

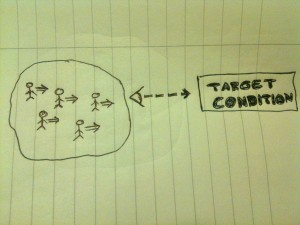

I wish managers out there asked themselves why they have output targets, and from that see if they also know where they are heading; if they have clear target conditions on all levels and for all processes. If all you got is targets, try to shift focus to target conditions instead. Help the organization and all employees establish target conditions describing how their process should work a few weeks ahead, and start improving accordingly. The number of improvements per employee will increase as a side effect. If you would like to be able to brag to your competitors, then by all means, collect the metric and celebrate the score you get, but do not make it the main focus. Because, I hardly think that you run the company to produce improvements; you do it in order to produce customer value, right?

I wish managers out there asked themselves why they have output targets, and from that see if they also know where they are heading; if they have clear target conditions on all levels and for all processes. If all you got is targets, try to shift focus to target conditions instead. Help the organization and all employees establish target conditions describing how their process should work a few weeks ahead, and start improving accordingly. The number of improvements per employee will increase as a side effect. If you would like to be able to brag to your competitors, then by all means, collect the metric and celebrate the score you get, but do not make it the main focus. Because, I hardly think that you run the company to produce improvements; you do it in order to produce customer value, right?