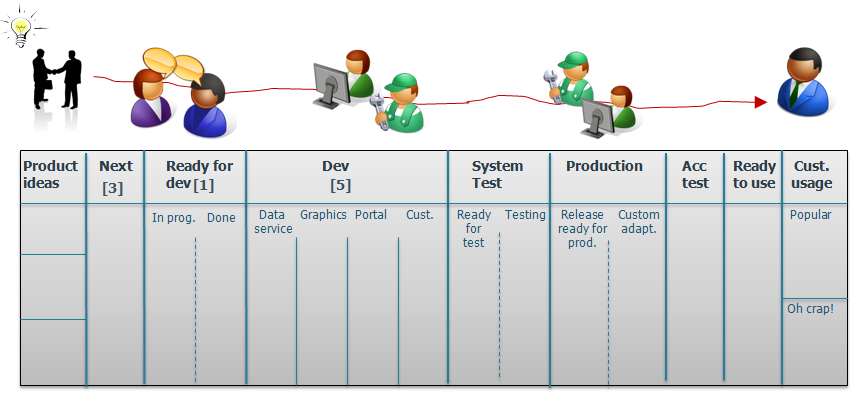

What happens when we apply kanban across the full value chain? What if you are a traditional company, how far can you improve before organizational structures becomes your key constraint? Can you make great products in a multi team scenario without product owners and project managers?

Let me share with you our learning of applying Enterprise kanban in a traditional company.

What we found:

- We improve time to market by 2x in 1.5 year

- 95% of shipped product ideas reported value adding

- We delivered our products without use of Product Owners, Project managers or a Project Office

(we did however have a marketing function, so another way to put it – it can allow product people to spend more time out with customers) - Enterprise kanban, Concepts, collaborative design and facilitation were our main tools

Read the full case study here.

As always, always make sure you use ideas wisely in your context. Never copy, always improve.

Cheers

Mattias Skarin

Interesting case study. Thanks for posting.

Though I am not totally convinced “enterprise kanban” is the whole solution. Is it the culture of clarity and communication that it promotes that is the real solution?

James

Hi James

You are totally right, it it not the complete solution. Some other pieces are for example lean leadership (build quality in, focus on improving flow over satisfying the need of individual functions), problem solving, culture of solving problems together.

A subtle thing easily missed is how enterprice kanban shifted the language and communication. It put the focus on the products, and what prevented them from moving forward, instead on a million other things. Not sure if this is the same as the culture of clarity which you are referring to 🙂